Accueil

Le spécialiste de

l’humidification

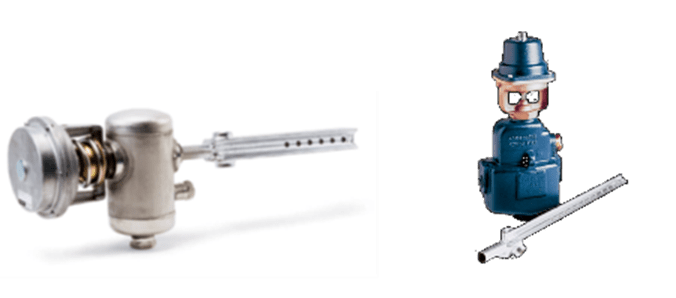

Reconnus pour leur fiabilité et leur haute technologie, les produits Devatec vous offrent la solution à vos problèmes d’humidification.

Boostez vos économies d’énergie avec nos systèmes d’humidification et de refroidissement adiabatique

+

40

ans

Dans l'humidification

+

60

Pays

5